- #PLC SOFTWARE SIMULATOR MANUAL#

- #PLC SOFTWARE SIMULATOR PRO#

- #PLC SOFTWARE SIMULATOR CODE#

- #PLC SOFTWARE SIMULATOR PASSWORD#

- #PLC SOFTWARE SIMULATOR SIMULATOR#

Robotics Simulation Training | Pegasus Servo Robot Operation & Programming.

Robot Integration | Mechatronic Systems.PLC Project Station - AB Micro810 | 87-PPSAB1.PLC Program Simulation Training | Hands-On Training with a Siemens S7-1500 PLC.

#PLC SOFTWARE SIMULATOR SIMULATOR#

#PLC SOFTWARE SIMULATOR MANUAL#

#PLC SOFTWARE SIMULATOR PRO#

Schneider Electric did not immediately respond to a request for comment.Īnother limiting factor is that a potential attacker already needs to have access to a computer on the network that can communicate with the Unity Pro engineering workstation in the first place.Īccess to such a computer can be obtained in a number of ways, including through malware attacks, other vulnerabilities and even malicious insiders. However, "it is up to the user to select the Unity PRO default application to be launched by the simulator, and to protect this application program by a password," the company said in the advisory.

#PLC SOFTWARE SIMULATOR PASSWORD#

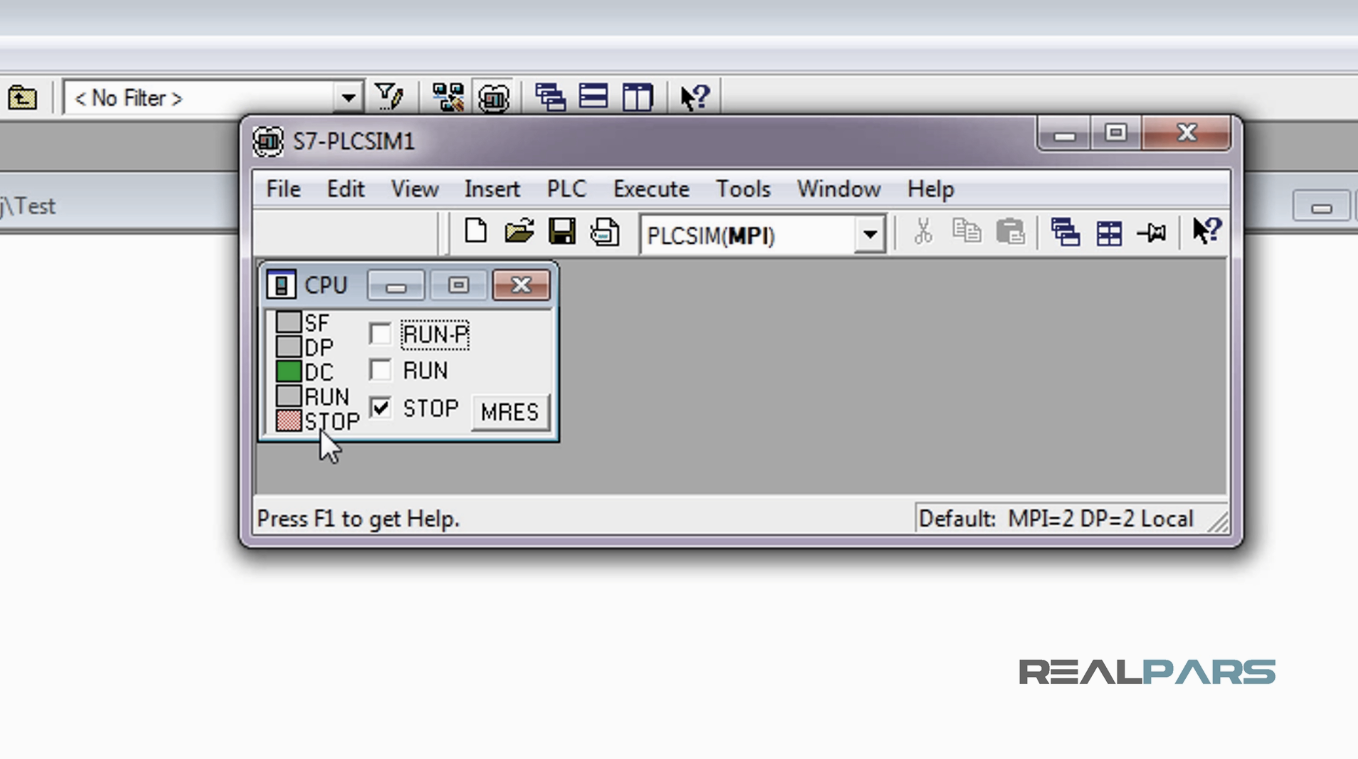

Even if there are firewalls separating PLCs from the rest of the network, engineering workstations will always be whitelisted and will be able to communicate with them because that's their role.Īccording to a Schneider Electric security advisory regarding this issue, there are is at least one limiting factor: the attack will only work if there's no other application program running inside the PLC simulator or if that application is not password protected.īecause of this, the newly released Unity Pro version 11.1 will not allow the simulator to be launched without an associated application.

#PLC SOFTWARE SIMULATOR CODE#

Breaking out of this process is trivial because there is no sandbox or code isolation, he said.īecause of their privileged position, engineering workstations are what Gandelsman calls the crown jewels of industrial control networks. The problem is that this process runs with debug privileges on Windows so you can do anything you want to the machine, said Mille Gandelsman, CTO of Indegy. apx file that contains malicious x86 instructions and which the Unity Pro software will execute in a child process. The Indegy researchers found that they can craft an. apx files to be executed by the Unity Pro PLC simulator without authentication. The simulator supports binary formats for different Schneider Electric PLCs, including for those using the x86 architecture. Furthermore, they could provide them with access to intellectual property such as secret recipes for products that are being manufactured and which can be derived from the legitimate programs deployed to PLCs.Īccording to the Indegy researchers, the Unity Pro PLC simulator opens a network service on workstations that listens on a specific TCP port and allows remote computers to send control code packaged in a proprietary format to the simulator.Īny computer that can communicate with the engineering workstation over the network can send. Since Unity Pro is typically installed on engineering workstations, a compromise of those systems would provide attackers with the ability to reprogram in-production PLCs and interfere with critical processes.

0 kommentar(er)

0 kommentar(er)